CMM Software

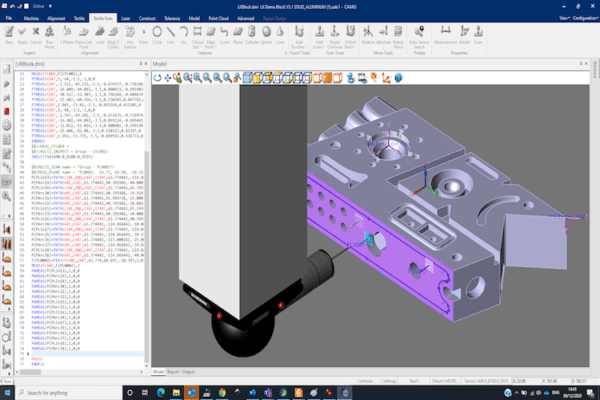

TouchDMIS

TouchDMIS is an advanced CMM measurement software, designed to optimize the measurement process with a fully touch interface.

Gọi (+84) 828 31 08 99 để được tư vấn.

Technical Description

TouchDMIS is an advanced coordinate measurement (CMM) software designed to optimize the measurement process with a full touch interface, providing an intuitive and easy-to-use user experience. The software supports full integration with CAD and sophisticated sensors, increasing productivity and measurement efficiency.

Outstanding features

Intuitive touch interface:

- TouchDMIS is designed with a touch interface that is easy to use and intuitive, allowing the user to have complete control over the measurement process with just a touch.

- There is a 3D simulation mode suitable for training beginners.

- The interface has large icons and a clear layout that makes it easy for users to manipulate and navigate with common operations such as swiping, zooming in, and zooming out.

Optimized for touch devices:

- The software is optimized to run smoothly on touchscreen devices, allowing users to operate quickly and accurately.

Various measurement functions:

- TouchDMIS supports a wide range of measurement functions, from point, line, plane to complex shapes.

- Supports inspection and measurement of parts with high precision, meeting the needs of various industries.

Supports multiple probe types:

- The software is compatible with a wide range of probes, including contact and non-contact probes, providing increased measurement flexibility.

CAD Integration:

- TouchDMIS is capable of integrating with CAD software, allowing users to easily import and export data from STEP, IGES and other popular CAD formats.

- Supports display and processing of 3D CAD models, allowing users to check and validate measurement details directly on the model.

Detailed measurement results report:

- The software provides powerful reporting tools, allowing the creation of detailed and professional measurement reports.

- Support exporting reports in many formats, suitable for storage and sharing needs

TouchDMIS Measurement Functions

- Examine geometric features such as lines, planes, circles, cylinders, and other geometric shapes.

- Check freeform shapes that do not follow standard geometries, commonly found in complex surfaces and parts with special shapes.

- Automatically recognizes the type of feature to be measured, saving time and minimizing errors during measurement.

- Automatic confirmation of characteristics in manual measurement mode, optimizing manual measurement process.

- Build geometries with automatic shape recognition, improving measurement accuracy and performance

- Relative measurement between points or features on a part, aiding in inspection and testing applications.

- Create and examine cross-sections of parts, allowing analysis and measurement of internal features.

- Align parts based on geometric features, freeform shapes and RPS (Reference Point System) method.

- Repeatable alignment based on reference point system, ensuring high accuracy during measurement.

- Measure gaps, clear planes and clear boxes.

- Check and tolerance dimensions, geometrical features GD&T (Geometric Dimensioning and Tolerancing), ensure details meet technical requirements.

- Displays DMIS (Dimensional Measuring Interface Standard) program blocks and command codes, supporting programming and testing of measurement programs.

- Advanced DMIS programming and parameters, along with macros to automate and optimize measurement processes.

- Different feature calculation algorithms, which help to improve measurement accuracy and efficiency.

- Filter the arithmetic points to remove noise and increase the accuracy of the measurement data.

- Drawing environment for building and reporting 2D structures, supporting visual and detailed report generation.

- Locate CAD models for offline inspection, allowing inspection and measurement without direct connection to measuring equipment.

- Edit point clouds, compare cross sections, extract features and mesh point cloud data, supporting detailed analysis and inspection.

- Find and measure holes on parts, assisting in inspection and assembly.

- Measure thread holes, check and confirm thread holes on the part.

- Repeatable measurement method, which helps to expand the measuring range without moving the device.

- Create and measure level planes, aiding in alignment and measurement.